More details of wall panel production machine

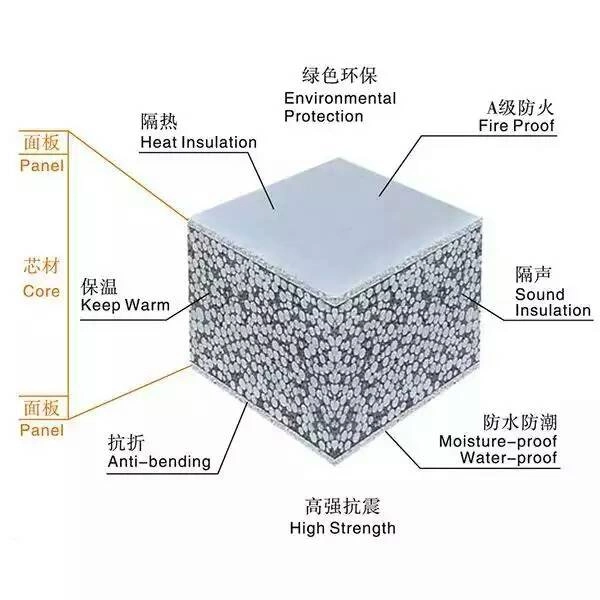

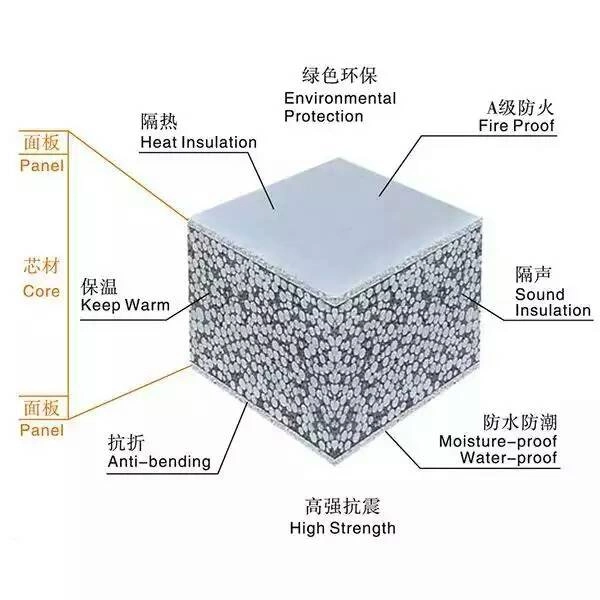

Now why eps wall panel is more and more popular?

1 -lightweight :The lighter material of the wall panel used weighs 25% to 40% of the weight of the bricks

2 -High thermal insulation

3 - Remove a higher sound

4 -Install faster 4 Times than the regular blocks

5 - Wall does not need the expenses of the work of the plaster

The advantage of wall panel than bricks

Our factory -warehouse-60000 SQM

OYD group was established in 2008. she has 5 subsidiaries for producing different kinds of products, eps concrete wall panel production line; mgo board /fiber cement board production line; hollow glass aluminum spacer; Laser cutting machine , etc.

Our proejct in Middle East

We have a project , you can check its pictures . For this project, they only had 4 sets mold cars at beginning, and this year with their market is larger, they order more molds cars from us.

So dear, this project is very flexible in production capacity and investment. As engineer will configure this whole linNo need to buy others parts.e for you based on a larger production capacity. So when your market is larger, you will only buy more mold cars.

FAQ

Contact Us

I am Sherry from Shandong Oyade Machinery, China.

Our factory has been producing wall panel production line for 15 years, and have successful projects in Philippines, Malaysia, Qatar, UAE, Syria,Saudi Arabia, Russia, Australia, Ecuador, Mexico and so on.

https://yurui2018.en.made-in-china.com

Now why eps wall panel is more and more popular?

1 -lightweight :The lighter material of the wall panel used weighs 25% to 40% of the weight of the bricks

2 -High thermal insulation

3 - Remove a higher sound

4 -Install faster 4 Times than the regular blocks

5 - Wall does not need the expenses of the work of the plaster

The advantage of wall panel than bricks

| Shandong Oyade Group | ||

| The advantages of EPS sandwich Wall Panel than traditional block | ||

| Item | New type EPS sandwich lightweight Wall Panel | Traditional AAC block |

Specification | 120mm*2440*610 | 200mm |

sound insulation | Due to the wall as a whole panel make its performance is uniform distribution, the overall sound insulation effect is good ,, | The wall has a lot of joints to reduce noise performance,Block masonry distribution largely affect the sound insulation effect; |

| Fire Resistance | The fire resistance limit is 2.5-4 hours,Noncombustion reached the national standard A grade,and can be used in the fireproof building. | The fire resistance limit 1 hours |

| Anti-seismic | Whether the frame or steel structure, due to the big board overall installation for use as a wall structure form, so it can be adapted to larger interlayer displacement angle and greatly enhance the seismic resistance | Requires masonry and structural reinforcement as a wall material, the seismic resistance is worse than the EPS wall panel |

| Water-Resistance Ability | The surface board is the high density calcium silicate board, core material containing water retaining agent, so it has good waterproof effect | Non water-proof |

| Machinery Parameters | |

| Configuration: | Automatic metering system |

| Capacity | 20,000sqm~600,000sqm per year |

| Thickness | 50-250mm thickness. |

| Length | 2440~3600mm, |

| Width | 610mm , |

| Raw materia | There are mainly two different types |

| 1. Cement+fly ash/eps/ceramsite/sand | |

| 2. Foamed cement+additives | |

| Finished board type | 1. Composite board/sandwich board, with surface board |

| 2. Lightweight solid panel, without furface board | |

| Surface board types | 1. Calcium silicate board |

| 2. Fiber cement board | |

| 3. Mgo board | |

Our factory -warehouse-60000 SQM

OYD group was established in 2008. she has 5 subsidiaries for producing different kinds of products, eps concrete wall panel production line; mgo board /fiber cement board production line; hollow glass aluminum spacer; Laser cutting machine , etc.

Our proejct in Middle East

We have a project , you can check its pictures . For this project, they only had 4 sets mold cars at beginning, and this year with their market is larger, they order more molds cars from us.

So dear, this project is very flexible in production capacity and investment. As engineer will configure this whole linNo need to buy others parts.e for you based on a larger production capacity. So when your market is larger, you will only buy more mold cars.

Production schedule

EPS Sandwich wall panel production line production schedule | ||

Commencement date of the contract: Contract production cycle: 45 working days | ||

No. | Item | Time node |

| 1 | Confirmation of planning scheme, Completion of basic drawing and preparatory work. Standard parts, mold car will arrange workshop. | |

| 2 | After the customer confirms the plan, we will complete the design of steel structure drawing within one week. The drawings issued in batches to workshop, we will arrange the production | |

| 3 | Production on purchasing necessary parts according to the drawing, assembly and commissioning. | |

| 4 | Spray paint, packaging | |

| 5 | Loading to container | |

| Loading details: Loading: 40HQ*4 (including 2* 40 HQ and 2* 40OT | ||

FAQ

| 1. | How to curing the wall panel ? |

| Normally curing time is 8-12hours , it can adjust according to your local temperature , also need natural curing around 25-28days before use it . | |

| 2. | Q: How long is the warranty of your equipment? |

| A: 1year ,but we will provide after-sale service the whole life cycle | |

| 3. | Q: Do you supply spare parts? |

| A: Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year. Other parts we will provide price list in advance . | |

| 4. | Q: Will you provide trainning and formula? |

| A: The training is free of charge , and our engineer will be on duty to train your worker until they know how to produce qualifyed product .Also we will provide you qualified formula | |

| 5. | Q: How will you provide installation&commissioning |

| A: Will provide 2~8persons(adjustable according to the degree of automatic )for installation.Engineers team will go with your project. , besides we only need 15days for commission .in this way can help you save cost on raw material and time . |

Contact Us

I am Sherry from Shandong Oyade Machinery, China.

Our factory has been producing wall panel production line for 15 years, and have successful projects in Philippines, Malaysia, Qatar, UAE, Syria,Saudi Arabia, Russia, Australia, Ecuador, Mexico and so on.

https://yurui2018.en.made-in-china.com